The above video shows you how to fit Masai Panoramic side windows to Defenders with factory-fit windows that you want to replace AND to Hard Top / Panel Vans that need an aperture cut out.

Fitting Masai Panoramic Windows to a Defender as Replacements

NOTE If you have a Hard Top/Panel Van Defender click: fitting Masai Panoramic Windows to a Hard Top Defender

You can fit Masai Panoramic Windows to your Land Rover Defender in just a few hours – back on the road the same day, as the special window adhesive sticks permanently quite quickly. We do not recommend that you wash your vehicle or leave out in the rain for 24 hours.

Please watch our video and study the instructions supplied; make sure you have all the tools and other equipment ready before you start, including a table near your vehicle. Please follow widely accepted Safety Precautions, we cover some of them at the foot of this page.

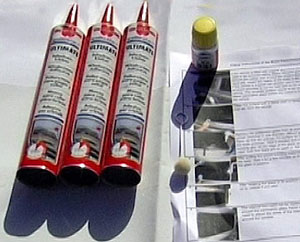

The Bonded Windows Fitting kit

The Bonded Windows Fitting Kit includes surface primer, an applicator swab for the primer, polymer adhesive and cleaner wipe. We sell this kit, but due to customs restrictions we cannot ship it outside the UK. We have a kit with two 310ml tubes of adhesive – needed for fitting a pair of side windows. We also have a kit with just one 310ml adhesive tube – this kit is for fitting rear panoramic quarter lights or rear door glass. These kits can be found HERE

The tools and equipment you will need to have ready in advance:

- A table at least 4 foot long to put the glass on whilst applying the primer and adhesive, if not then use the cardboard box that the windows came in.

- Cloths and mild cleaning agent to make sure all surfaces are clean.

- Latex gloves – the primer and adhesive is difficult to remove if you aren’t careful.

- An electric extension cable.

- An electric drill and an 8mm drill bit for metal.

- Eye and ear protectors when you use the drill.

- An applicator gun for use with standard sealant tubes

Put the tubes of adhesive in a bucket of hot water (not boiling – ideal is 30 degrees C, 86 F) and get the adhesive applicator gun ready.

Removing factory-fit side windows

Using an implement such as a screwdriver remove the window seal beading strips, drill off the rivet heads and carefully take out the aluminium window frames from both sides of your vehicle.

Preparing the surfaces and applying the adhesive

Clean the outside surfaces of the side of your vehicle surrounding the aperture and also clean the glass. Clean surfaces are important to ensure the primer bonds properly.

Complete one side at a time – decide which side you are doing first – you can tell which window goes on which side as the Masai logo should be the right way up and you need to offer up the windows to see which is which.

Lay the first window on a table, with cardboard or newspaper protection – so that the inside, the aluminium frame side is facing up.

Put on some latex gloves – as the primer and adhesive is very sticky and hard to remove.

TAKE NOTE – You are going to be applying the special primer in a continuous line WITHOUT over-painting what you have done – one stroke only – as it dries very quickly and you may deactivate it if you over-paint.

Shake the preparation primer and CAREFULLY remove the lid.

Don’t use too much or too little primer – use an even amount so there are no really wet parts nor patchy parts (not enough primer on the applicator swab). Wipe the applicator against the inside edge of the primer bottle when with-drawing to ensure there is not too much primer on the applicator that it drips – it sticks very well to all surfaces – so be very careful indeed.

Practice painting a few lines on the section you have cut out, or on another non-important clean, smooth, non-absorbent surface.

Using the applicator apply the primer in neat straight lines along the outer edges of the glass – about 5 mm from the edge, with two extra lines on the larger side and one extra line on the smaller side. Join the lines – no gaps. See photo and video.

Immediately go to the vehicle and apply the primer in the same way – paint the same pattern of lines that you made on the glass around the aperture you are doing first – you are completing one window at a time. Again – join the lines – no gaps. Screw the lid back on the bottle as soon as you are finished.

Immediately get one of the adhesive tubes from the bucket, dry it, insert into gun and remove lid, test on a piece of newspaper to see that the gun is prepared and the adhesive extrudes from the nozzle correctly.

Without delay start to apply the adhesive (see photos) on top of all the lines you have make with the primer on the glass (not the vehicle).

The triangular cut-out in the nozzle needs to face upwards.

Make a continuous pyramid shape line along and on top of all of the primer lines (see photo and video). Make sure there are no gaps – particularly the top edge – to ensure no leaks.

Fitting the Windows

The primer and adhesive application process should be done within 10 to 15 minutes and immediately after carefully carry the window to the vehicle and press it firmly into position.

You will need two people to do this. First priority is to make sure the top edge is parallel to the rim of the roof and the rear side is parallel to the vertical side of the vehicle.

The adhesive bonds straight away to the primer on the vehicle but will take 24 hours to really cure.

Keep continuous pressure on all parts of the glass for at least 10 minutes to ensure it is properly stuck evenly all around.

Repeat the whole process with the other side of the vehicle.

You may need to adjust some of the internal trim if necessary to fit around the window.

Also see: Fitting the Rear Quarter Lights

Safety Precautions

Before embarking on a DIY project, it’s essential that you take the proper safety precautions. Wear protective clothing including safety goggles, gloves, hearing mufflers when working with potentially hazardous materials and equipment such as primers, solvents, adhesives, glass, electric drills and saws. Always use the correct tools for the job. It is worth investing in high quality equipment as this will be safer and will probably do the job quicker.

Don’t rush as you’re more likely to have an accident. Carefully plan the job before you start work. Know your limitations and consult a professional if you are unsure. It’s also a good idea to ask someone if they can help you. Unplug drills and jig saws before fitting parts and remove the chuck key before switching on. We cannot be held responsible if you do not follow safety precautions or do not follow instructions exactly.